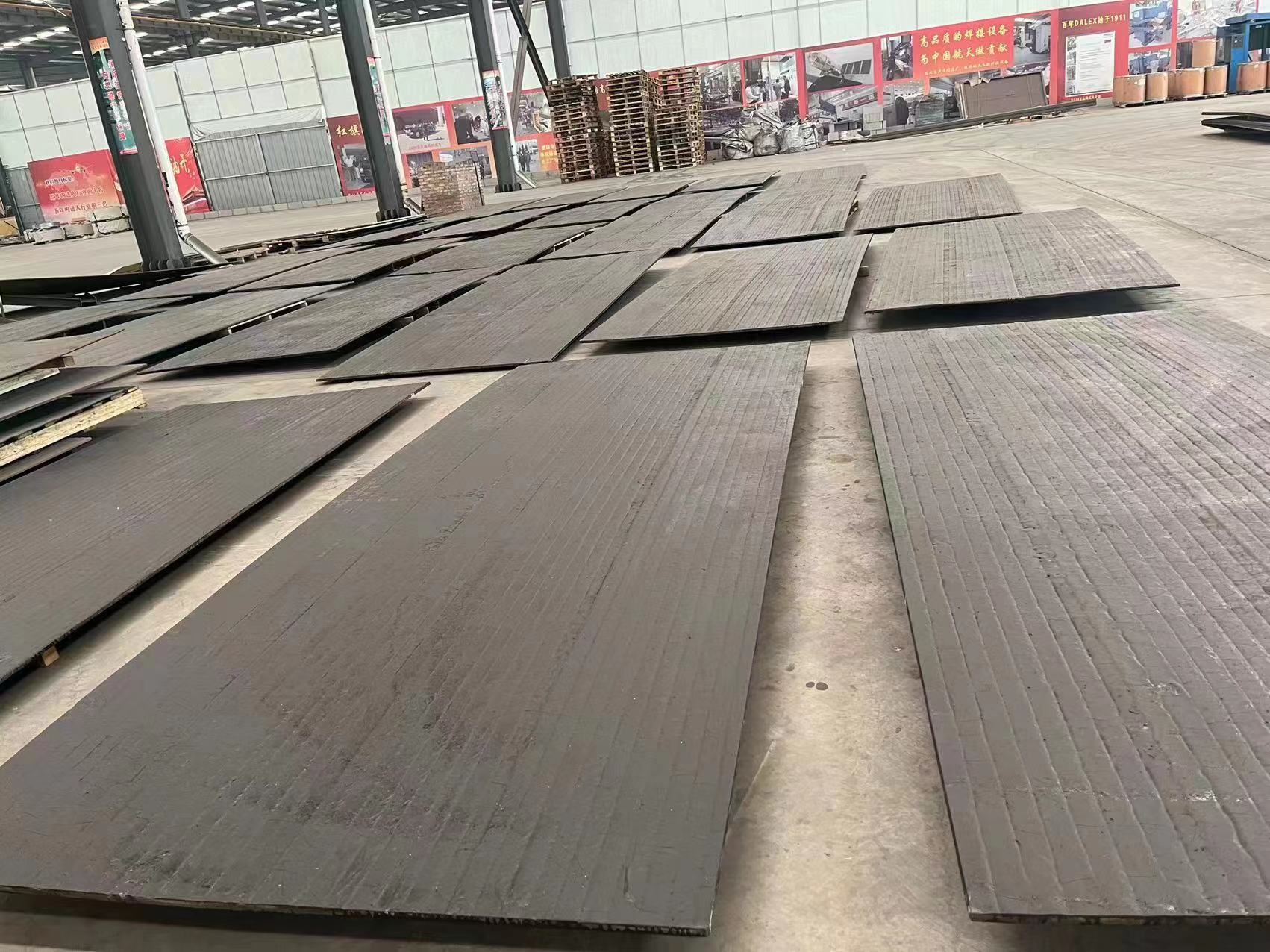

Introduction to Surfacing Wear Resistant Plate:

Our product Surfacing Wear Resistant Plate is a material used to protect equipment surfaces from wear and corrosion. This Surfacing Wear Resistant Plate has various models, namely: 10+10 wear resistant plate, 3on3 wear resistant plate, 4on4 wear resistant plate, 8on8 wear resistant plate, 10on10 wear resistant plate. Surfacing Wear Resistant Plate is composed of two layers of different materials. The bottom layer is a substrate material with good toughness and weldability, while the top layer is an alloy material with good wear resistance.

Advantages of Surfacing Wear Resistant Plate:

1. Good wear resistance: The top alloy material used in this Surfacing Wear Resistant Plate has excellent wear resistance and can effectively resist wear and friction.

2. A variety of models to choose from: This Surfacing Wear Resistant Plate has a variety of models to choose from, including 10+10 wear resistant plate, 3on3 wear resistant plate, 4on4 wear resistant plate, 8on8 wear resistant plate, 10on10 wear resistant plate .

3. Strong high-temperature performance: This Surfacing Wear Resistant Plate can maintain stable performance in high-temperature environments and will not be damaged or deformed due to high temperatures.

4. Good Weldability: The material of our Surfacing Wear Resistant Plate has good weldability and can be easily installed and surfacing.

Application areas of Surfacing Wear Resistant Plate:

1. Mining industry: The product cladding wear-resistant plate can be used for the transportation of ore, which can effectively resist wear and impact and extend the service life of the equipment.

2. Metallurgical industry: In the process of metallurgical iron-making and steel-making, Surfacing Wear Resistant Plate can be used for blast furnace lining and ladle lining. It can resist high temperature, corrosion and wear, and can improve the durability of equipment.

3. Electric power industry: Surfacing Wear Resistant Plate can be used for the lining of equipment such as coal conveying systems in thermal power plants and can resist wear and high temperatures.

Welding Consumables Processing Workshop:

The company only had 2 welding wire production lines when it was first established. After equipment renovation and new equipment put into production, it has developed to 6 flux-cored welding wire production lines, with a daily output of 15 tons and a comprehensive annual output of 5,000 tons. With the development of the company, the scale continues to expand.