Brief introduction of Special Wear-resistant Plate For Steel Mills:

The Special Wear-resistant Plate For Steel Mills we produce is a special wear-resistant material, which can be widely used in a variety of equipment and components in the iron and steel industry.

Special Wear-resistant Plate For Steel Mills has excellent wear resistance and impact resistance, which can effectively prolong the service life of the equipment and improve production efficiency.

Our series of products include Composite wear resistant steel plate, Chromium carbide wear plate, Wear Liner, Welding Wear Pipe and Wear resistant chute.

In the production of products, we use high-hardness materials, the surface has been specially treated to form a hard wear-resistant layer.

Our series of Special Wear-resistant Plate For Steel Mills products can be customized according to your needs. If you are interested in our products, please feel free to contact us.

Advantages of Special Wear-resistant Plate For Steel Mills:

We can provide you with many types of wear-resistant plates, including Composite wear resistant steel plate, Chromium carbide wear plate, Wear Liner, Welding Wear Pipe, Wear resistant chute.

It can meet the wear-resistant needs of your steel mill in all kinds of equipment and parts.

Composite wear resistant steel plate is made of high strength composite alloy materials with excellent wear resistance.

The surface of Chromium carbide wear plate is specially treated to form a hard wear-resistant layer of chromium carbide with high film resistance.

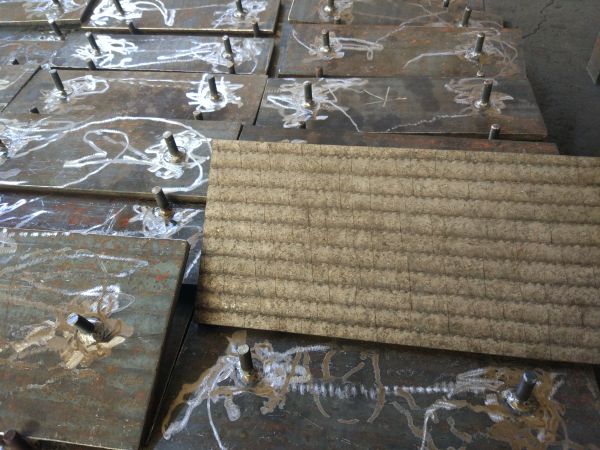

Wear Liner can be fixed to the inner wall of your equipment by welding, which can withstand impact and has high wear resistance.

Welding Wear Pipe is a pipe with wear-resistant layer, which is suitable for conveying high-speed flow or granular materials.

Wear resistant chute can be used for material transportation and handling in your steel mill.

It is convenient for you to transport materials.

Welding Consumables Processing Workshop:

The company only had 2 welding wire production lines when it was first established. After equipment renovation and new equipment put into production, it has developed to 6 flux-cored welding wire production lines, with a daily output of 15 tons and a comprehensive annual output of 5,000 tons. With the development of the company, the scale continues to expand. In order to meet the market demand.