Introduction of On-site Welding Repair Service:

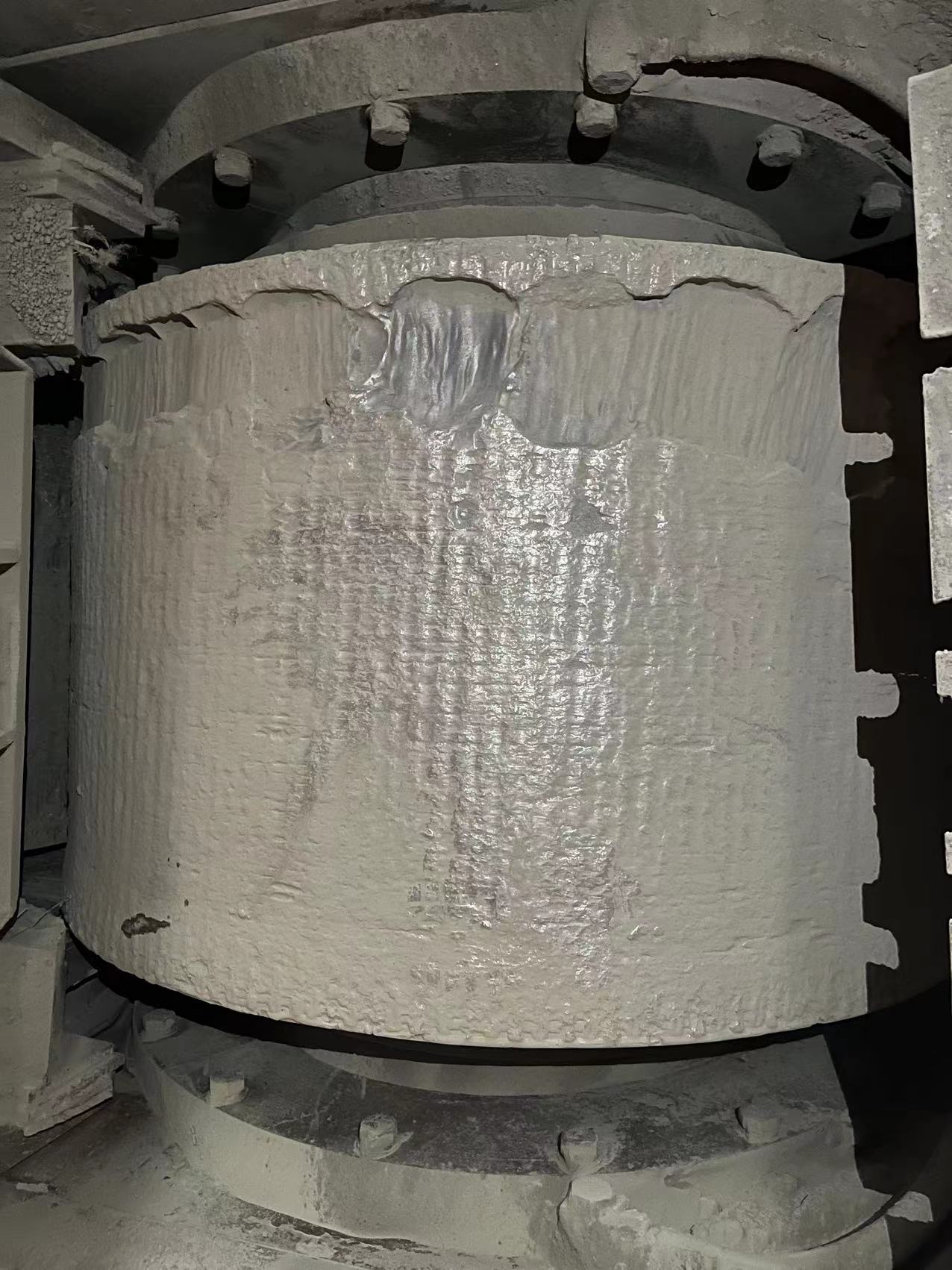

Our services include Grinding roller repair, Grinding roller remanufacturing, Industrial grinding disc lining plate surfacing welding, Roller crusher welding, Roller Crusher Repair, our service is a machine maintenance service, on-site surfacing repair, in order to solve various problems of machinery and equipment, such as corrosion, wear, fracture and so on.The way of surfacing repair can use a variety of welding techniques according to different conditions of the equipment, including ordinary manual surfacing and automatic surfacing, which is usually carried out by robots or other computer-controlled equipment. This service usually provides support to customers who are unable to shut down in production but need to repair the equipment.

In addition to repairing machines and equipment, surfacing repair services can also be used to enhance the reliability of the original product, thereby improving its performance and life. For example, Grinding roller repair, Grinding roller remanufacturing, Industrial grinding disc lining plate surfacing welding, Roller crusher welding, Roller Crusher Repair. When surfacing on site, technicians usually first conduct on-site assessment and inspection to determine the maintenance requirements of the equipment.

The appropriate welding material, such as chromium alloy or cemented carbide, will then be selected according to the type and damage of the equipment. After the welding is completed, adequate follow-up treatment, such as grinding, polishing or heat treatment, is required to ensure that the equipment returns to normal operation. Wearing personal protective equipment and following safety procedures and instructions are very important things in operation.

Grinding roller repair、Grinding roller remanufacturing、Industrial grinding disc lining plate surfacing welding、Roller crusher welding、Roller Crusher Repair is provided by professional technicians in our company. A successful project requires a high level of skills and appropriate work experience, including proficiency in different types of welding techniques, understanding of the characteristics of various welding materials, and respect for on-site environment and safety requirements. For customers, this service allows them to avoid large-scale downtime and equipment replacement, better control costs and improve production efficiency.

Our factory:

The company's surfacing workshop now has more than 20 sets of the most advanced automatic surfacing equipment, including wear-resistant plate surfacing machines, grinding discs, grinding roller off-line surfacing machines, wear-resistant pipe surfacing machines and a special test machine. Rich products, strong production capacity, annual output of wear-resistant surfacing plates is more than 80,000 square meters, complete follow-up processing equipment, can make all wear-resistant parts of vertical mills, wear-resistant parts for steel plant sintering workshops, continuous casting workshops, mines and other working conditions Consumables. Provide customers with more stable and durable wear-resistant products and technical services for a long time, and solve on-site wear problems, which are well received by the market and trusted by customers.