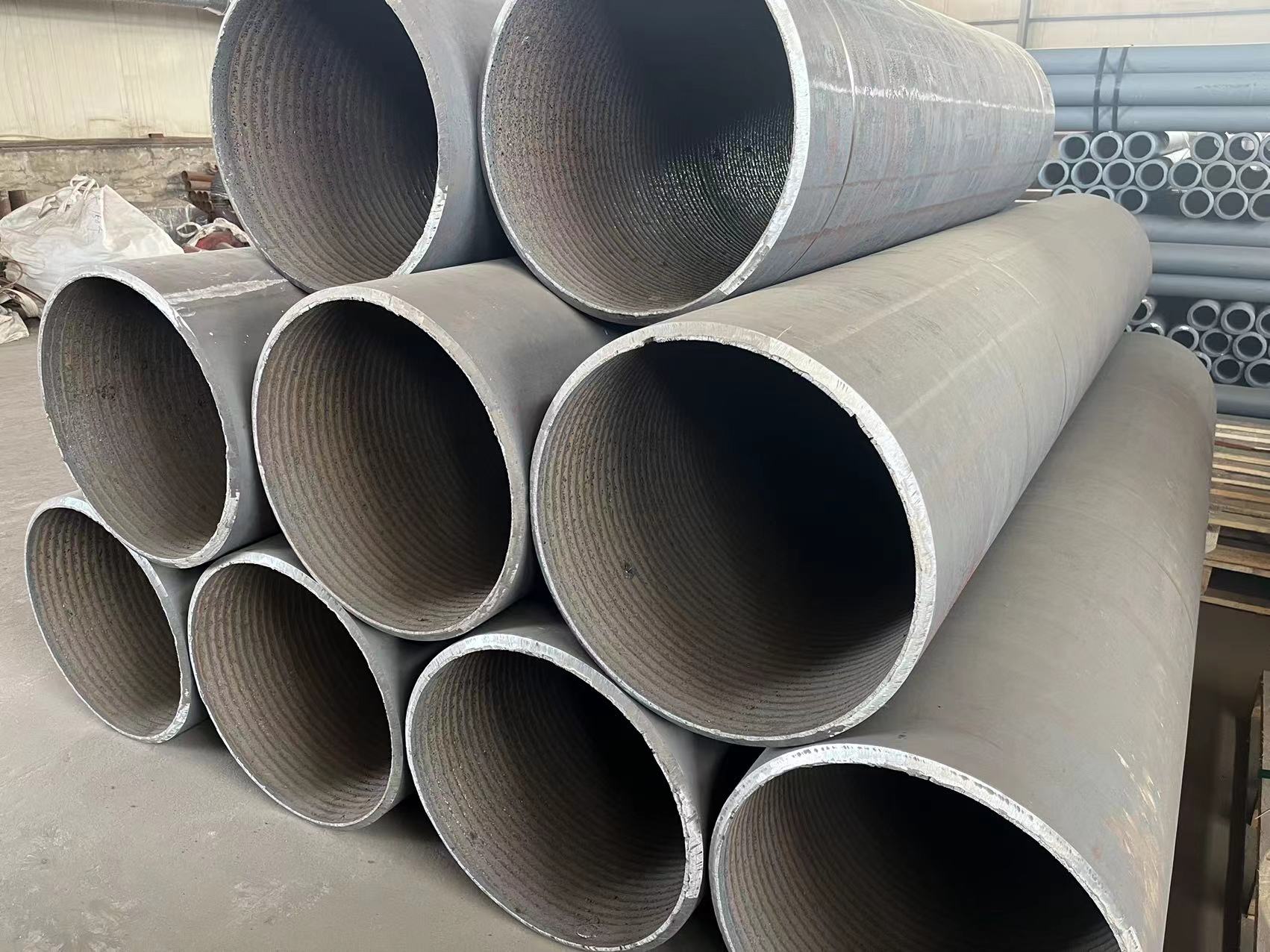

Introduction of Welding Wear Pipe:

Our Welding Wear Pipe is made of chromium carbide wear-resistant composite steel plate. The thickness of the wear-resistant layer of our Wear Resistant Pipes can be produced according to different applications. Our Chromium Carbide Wear Pipe has the dual properties of high hard material and ductile material, which can withstand moderate impact and vibration and prevent shedding.

Advantages of Welding Wear Pipe:

Compared with other alloy plates, ceramics, cast stone rubber and polyurethane, our Hardfacing Wear Pipe has the characteristics of good wear resistance and high toughness, and can be processed into various shapes at will. Wear Resistant Pipes has irreplaceable comprehensive excellent properties. Our Chromium Carbide Wear Pipe is easy to install, can be cut, welded, punched, bent, etc. Hardfacing Wear Pipe is suitable for different occasions, the wear resistance is 10-15 times that of ordinary wear-resistant materials, our Welding Wear Pipe has the characteristics of high temperature resistance, and does not affect the wear resistance.

Advantages of us:

Our company has rich experience and advanced surfacing technology in the field of surfacing products, and we can provide tailor-made solutions according to the needs of customers. We use high-quality materials and advanced surfacing technology to ensure reliable product quality. In after-sales service, we provide professional technical consultation, product debugging, after-sales maintenance and other omni-directional support to provide customers with timely and professional services. In addition, our company has a short delivery cycle and can meet the different needs of customers.

About us:

In the years of development, the company not only has strong manufacturing capabilities, but also has made important breakthroughs in research and development. The rotated laboratory is equipped with spark direct reading spectrometer, fluorescence spectrometer, carbon-sulfur analyzer, wear testing machine, Rockwell hardness tester, Leeb hardness tester, ultrasonic hardness tester and metallographic structure analysis microscope. Advanced scientific instruments can meet the requirements of product testing and product development.