Introduction of Chromium Carbide Grinding roller:

1. Wear Grinding roller grate bars: Grate bars are installed on the Chromium Carbide Grinding roller's grate bed and are responsible for supporting the sintering mixture during the sintering process. They provide a stable platform for the material to be sintered and allow for proper airflow and heat distribution.

2. Wear Grinding roller pallets: Chromium Carbide Grinding rollers are used to transport the sintering mixture on the grate bed. They are designed to withstand high temperatures and heavy loads, ensuring the smooth movement of the sintering material through the machine.

3. Wear Grinding roller burners: Burners are used to provide the heat required for the sintering process. Chromium Carbide Grinding rollers

are responsible for igniting the coke breeze and maintaining the desired temperature inside the sintering machine.

4. Wear Grinding roller fans: Fans are used to create a strong airflow within the sintering machine. They help in distributing heat evenly and removing the gases and dust generated during the sintering process.

5. Hardfacing Grinding roller dust collectors: Dust collectors are essential accessories for maintaining a clean and safe working environment. They capture and remove the dust and particulate matter generated during the sintering process, preventing them from being released into the atmosphere.

6. Hardfacing Grinding roller ignition hoods: Ignition hoods are used to ignite the coke breeze and initiate the sintering process. They provide a controlled environment for the ignition process, ensuring a uniform and efficient start to the sintering operation.

7. Hardfacing Grinding roller conveyors: Conveyors are used to transport the sintered material to the next stage of the steel production process. Hardfacing Grinding rollers

ensure a smooth and continuous flow of the sintered material, minimizing downtime and maximizing productivity.

Advantages of Welding Grinding roller:

1. Enhanced durability: Welding Grinding roller helps to strengthen the grinding roller, making it more resistant to wear and tear. This increases the lifespan of the Welding Grinding roller, reducing the need for frequent replacements.

2. Improved performance: Welding Grinding roller can help to correct any defects or imperfections in the grinding roller, ensuring smooth and efficient operation. This results in better grinding performance and a higher quality end product.

3. Cost-effective: By welding the grinding Hardfacing Grinding roller, you can extend its lifespan and avoid the need for expensive replacements. Welding Grinding roller helps to reduce maintenance and operating costs in the long run.

4. Customization options: Chromium Carbide Grinding roller allows for modifications and customizations to be made to the grinding roller, such as adding additional features or adjusting its dimensions. This enables the roller to be tailored to specific grinding requirements, resulting in improved efficiency and productivity.

5. Time-saving: Hardfacing Grinding roller can be a quick and efficient process, especially when compared to other methods of repairing or replacing grinding rollers. Welding Grinding roller helps to minimize downtime and maximize production output.

6. Versatility: Welding can be used on various types of grinding rollers, including those made from different materials or with different designs. Welding Grinding roller makes it a versatile solution for repairing or enhancing different types of grinding equipment.

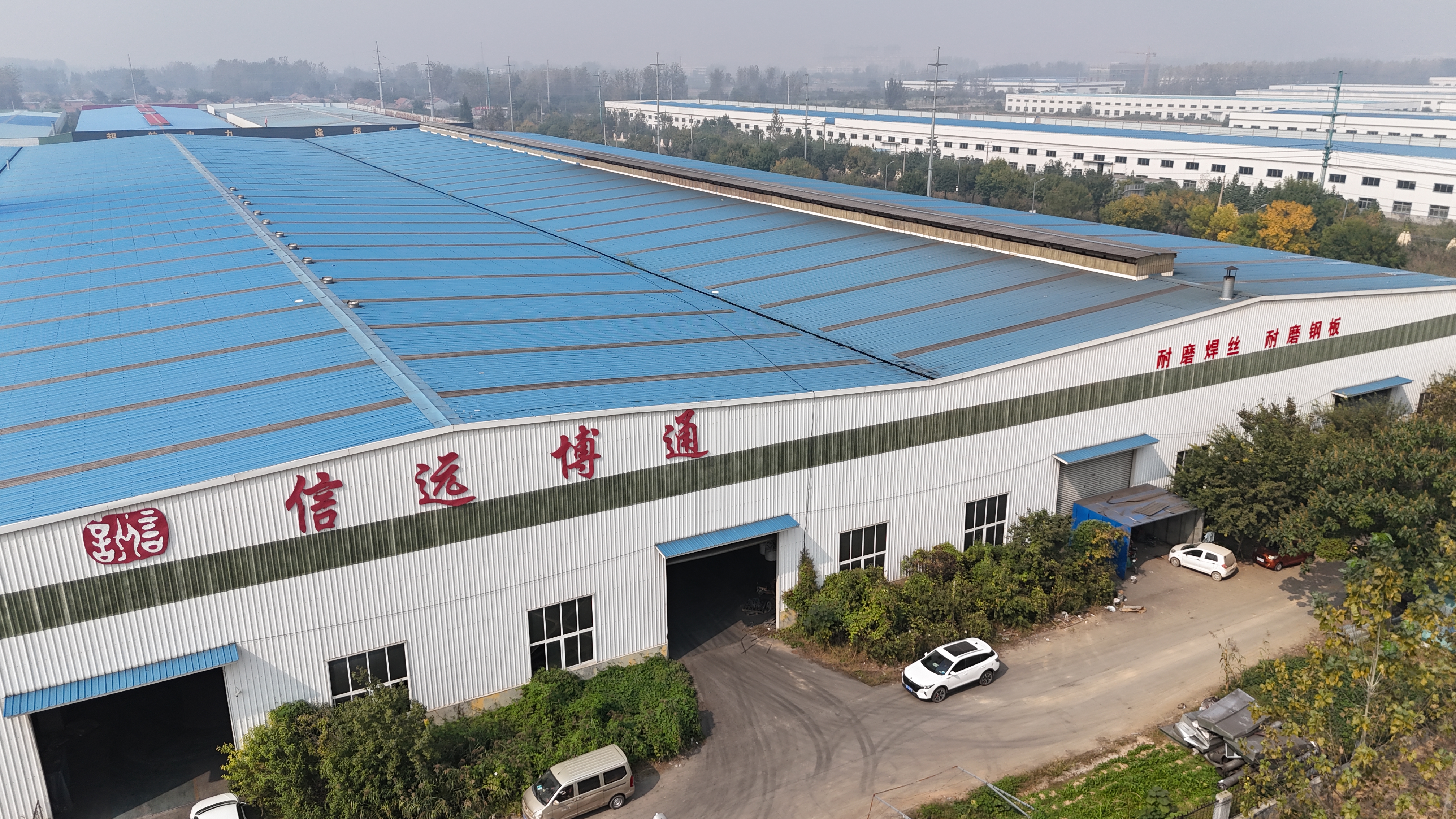

About us:

In the years of development, the company not only has strong manufacturing capabilities, but also has made important breakthroughs in research and development. The R&D laboratory is equipped with spark direct reading spectrometer, fluorescence spectrometer, carbon-sulfur analyzer, wear testing machine, Rockwell hardness tester, Leeb hardness tester, ultrasonic hardness tester and metallic structure analysis microscope. Advanced scientific instruments can meet the requirements of product testing and product development.