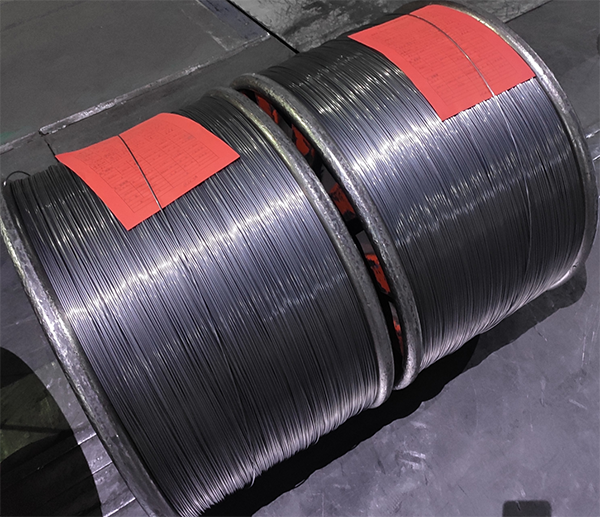

Introduction of HC-O welding wire:

Our CN-O welding wire is a welding material specially used for the maintenance and repair of cement vertical grinding mill equipment. 100Mo welding wire has high hardness and wear resistance, and Chromium carbide welding wire can effectively extend the service life of equipment and maintain its performance. Using our Wear resistant welding wire for repairs can save the cost of replacing the entire grinding disc and grinding roller, reduce production costs, and reduce equipment downtime.

Advantages of CN-O welding wire:

Good maintenance effect: HC-O welding wire can form a high hardness and wear-resistant coating on the surface of the grinding disc and grinding roller, providing excellent maintenance effect and extending the service life of the equipment.

High cost-effectiveness: By using CN-O welding wire for equipment maintenance, you can save the cost of replacing the entire grinding disc and grinding roller, while reducing equipment downtime and reducing production costs.

Convenient and fast: 100Mo welding wire is relatively easy to use. Just add Chromium carbide welding wire to the damaged part and weld it to complete the repair without replacing the entire part.

Why choose us:

We have extensive experience and expertise in the Wear resistant welding wire industry and can provide professional solutions and technical support. Our company's HC-O welding wire has a variety of characteristics and undergoes strict quality control to ensure that the quality of CN-O welding wire is stable and reliable. Our company attaches great importance to customer needs, adheres to the principle of customer first, and is committed to providing customers with the best 100Mo welding wire and services to meet customer needs and expectations. If you choose our company to cooperate, you will get high-quality 100Mo welding wire, professional technical support and complete after-sales service, helping you extend the life of your equipment, reduce costs, and improve production efficiency and competitiveness.

About us:

Our company's technical team has deeply studied the wear-resistant surfacing welding process, continuously developed and innovated with self-developed welding wires, and gradually launched products such as wear-resistant plates, wear-resistant pipes and derivative wear-resistant structural parts. Off -line surfacing and repairing grinding rollers and grinding discs are also launched at the same time, providing customers with high-quality and reputable services. Adhering to the spirit of craftsmanship and continuously improving the manufacturing process, we not only provide customers with excellent products, but also solve the problem of industrial wear and tear for customers. The products are well received by users and have been unanimously recognized.