Wear-Resistant Overlay Plate: Core Composite Material for Industrial Wear Solutions

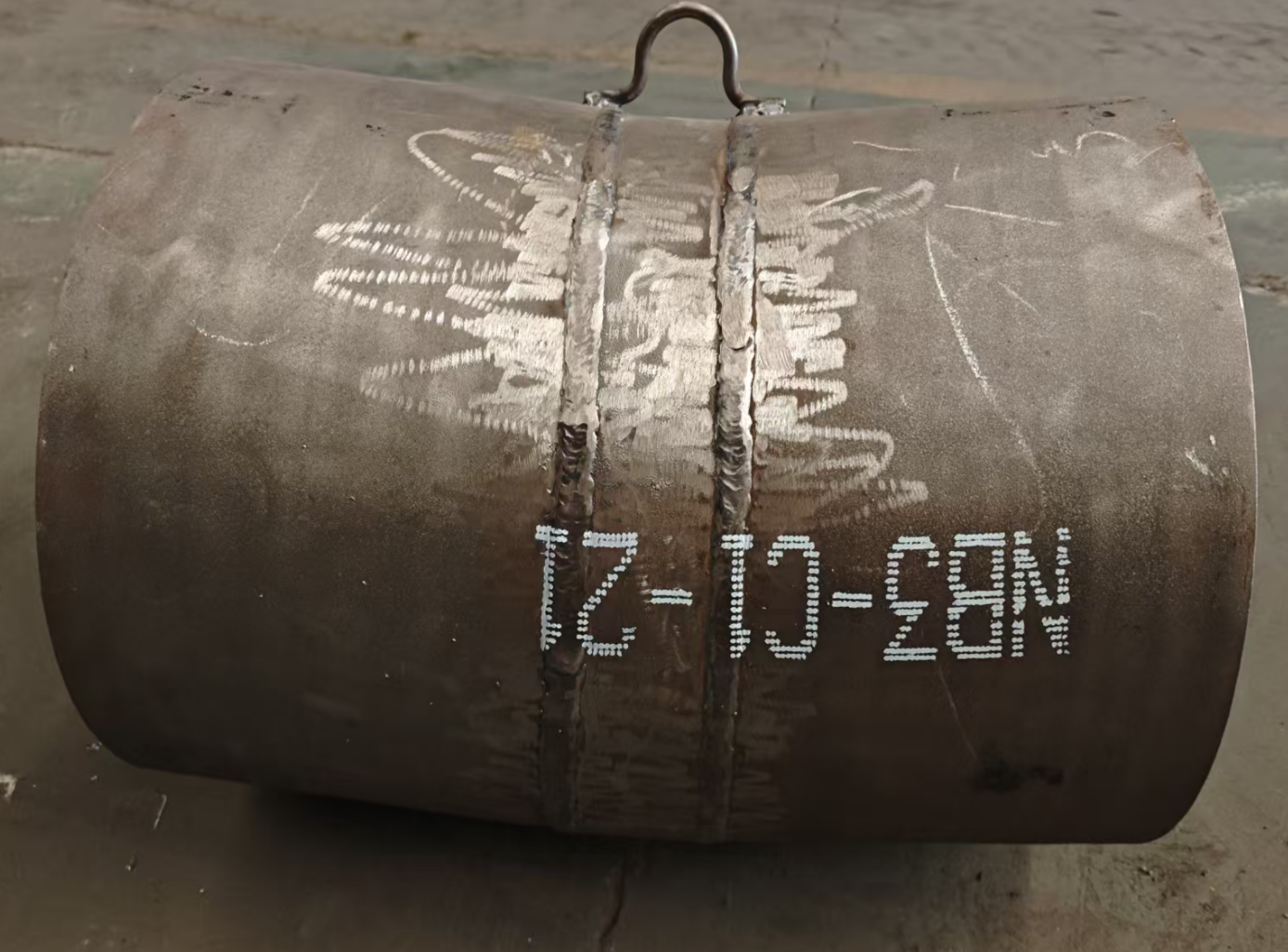

Wear-resistant overlay plates, a fundamental category of composite wear materials, utilize arc welding and submerged arc welding to deposit 3-20mm high-alloy wear layers (e.g., Cr26 high-chromium alloy, Mn13 high-manganese steel) on low-carbon steel substrates (Q235/Q355). This creates a "tough substrate + high-hardness wear layer" gradient structure, precisely addressing equipment failure under harsh conditions like impact loads, abrasive wear, and high-temperature corrosion. Applications are systematically categorized into four core industries:

I. Mining & Coal Industry – Impact-Abrasion Scenarios

Equipment faces combined cutting wear (from ore edges) and impact wear (from blasted materials). Customized overlays protect critical components:

•Conveyance System Corrosion Resistance

For ore chutes (≥45° incline), coal pipe elbows, and scraper conveyor troughs: Flux-cored open-arc welding deposits 5-8mm Cr26 alloy (HRC58-62), reducing wear rate from 0.3mm/month to 0.08mm/month. In an open-pit mine, component lifespan increased 4×, cutting annual downtime by 72 hours.

•Crushing Equipment Key Parts

•Jaw Crusher Plates: Bimetal overlay on Q345B substrate + 6-10mm Mn13-Cr2 alloy (impact toughness ≥15J/cm²) withstands 300MPa impact stress, eliminating premature wear.

•Cone Crusher Liners: Multi-layer welding with Ni-Cr buffer (crack suppression) and WC-Co top layer (edge wear resistance) extends service life from 800 to 2,500 hours.

•Grinding Mill Protection

Ball mill liners: Submerged arc welding deposits 8-12mm high-chromium iron (eutectic carbides ≥40%) on Q235. Waveform design enhances impact resistance, extending replacement cycles from 4 to 14 months while boosting grinding efficiency by 12% (gold mine case).

II. Construction Machinery – Dynamic Load Solutions

Addresses cyclic impacts and rock-cutting stresses:

•Excavator Bucket Systems

•Bucket Base: Plasma-transferred arc welding (PTAW) with WC particles (HV1200+) improves rock-scratch resistance 3×.

•Tooth Roots: Ni-Cr-Mo buffer layer (HRC35-40) reduces stress fractures, extending lifespan from 200 to 500 hours.

•Loader/Blade Edge Reinforcement

Twin-wire submerged arc welding on 5mm Q355 creates 8mm Cr15-C layer ("hard surface–transition–tough substrate"). Material penetration depth decreases from 15mm to 5mm, reducing replacement frequency from monthly to quarterly.

•Fatigue-Resistant Design

Bulldozer blades: Pulsed overlay welding with low-hardness HAZ transition layer (HRC35-40) prevents substrate embrittlement. High-hardness working layer (HRC55-60) resists cutting wear, increasing impact fatigue resistance by 20%.

III. Building Materials Industry – Abrasive Material Handling

•Cement Grinding Systems

Mill liners: High-Cr overlay (Cr≥25%) with "tortoiseshell mesh" reduces wear from 5g/ton clinker to 1.2g/ton (150°C). Roller press repairs via flux-cored wire restore hardness to HRC55-58 at 30% replacement cost (5,000t/day line saves ¥800k/year).

•Aggregate Processing Equipment

Sand maker impact liners: WC-particle overlay resists quartz abrasion (SiO₂≥90%), cutting wear rate from 0.5mm/day to 0.1mm/day. Mixer arms: 316L + Cr13 overlay solves cement corrosion + aggregate wear, extending life from 3 to 12 months.

IV. Power & Metallurgy – High-Temperature Wear Protection

Solutions for 300–800°C environments:

•Coal-Fired Power Systems

Coal chute elbows (material velocity ≥20m/s): High-Ni alloy overlay (Ni≥30%) improves oxidation resistance 3× (150-300°C), extending service from 6 to 24 months (300MW unit). Slag scraper blades: Cr-Ni-W alloy (≤600°C) reduces breakage by 60% (slag hardness HV800+).

•Metallurgical Rolling Systems

Hot-mill stands: Cu-based buffer + high-Cr overlay reduces gap wear from 0.5mm/month to 0.1mm/month under 2,000-ton forces. Converter mouth: Co-based alloy (Co≥50%) withstands 1,600°C steel splash, extending campaign life from 15 to 45 days.