In the field of industrial wear resistance, different application scenarios have diverse demands for wear-resistant plates, which has led to the emergence of personalized customization services. Xinyuan Broadcom, relying on 20 years of professional accumulation and rich experience in cladding technology, offers customized services for wear-resistant plate cladding and wear-resistant welding wire, dedicated to providing customers with wear-resistant solutions that fit their working conditions.

1. Scientific Material Proportioning:

Different customers have different wear plate usage conditions. For example, the characteristics of the materials in contact, including the hardness of the ore and the composition of the coal, as well as the operating environment of the equipment, including temperature, humidity, and the presence of corrosive substances. WoDun will carefully study this information and a professional team will formulate the alloy composition of the welding wire.

When used in high-hardness ore mining environments, the content of elements such as chromium, molybdenum, and tungsten in the wear-resistant plate should be appropriately increased to improve the hardness and resistance of the surfacing layer, so that the wear-resistant plate can better withstand the scratches and impacts of the ore.

When used in fields such as chemical or marine engineering where corrosive media exist, corrosion-resistant elements such as nickel and chromium are reasonably added to the wear-resistant plate to form a protective film, enhance the corrosion resistance of the surfacing layer, and avoid the performance degradation of the wear-resistant plate due to corrosion.

2. Precise performance matching Based on the customer's specific performance expectations for wear-resistant plates, such as wear resistance, impact resistance, surface hardness requirements, etc., Xinyuan Broadcom will achieve this by adjusting the manufacturing process and alloy ratio of the welding wire.

If the focus is on the impact resistance of wear-resistant plates, the proportion of elements such as manganese and nickel in the welding wire formula should be optimized, and appropriate treatment processes should be used to improve the toughness and impact resistance of the cladding layer and reduce the risk of deformation and damage. For example, the application of wear-resistant plates in engineering machinery buckets

If the precision manufacturing industry has high requirements for surface hardness, the carbon content should be precisely controlled and appropriate surfacing technology should be adopted to make the hardness of the surfacing layer uniform and reach the corresponding level to meet the needs of high-precision processing and long-term wear resistance, such as the application of wear-resistant plates in mold manufacturing.

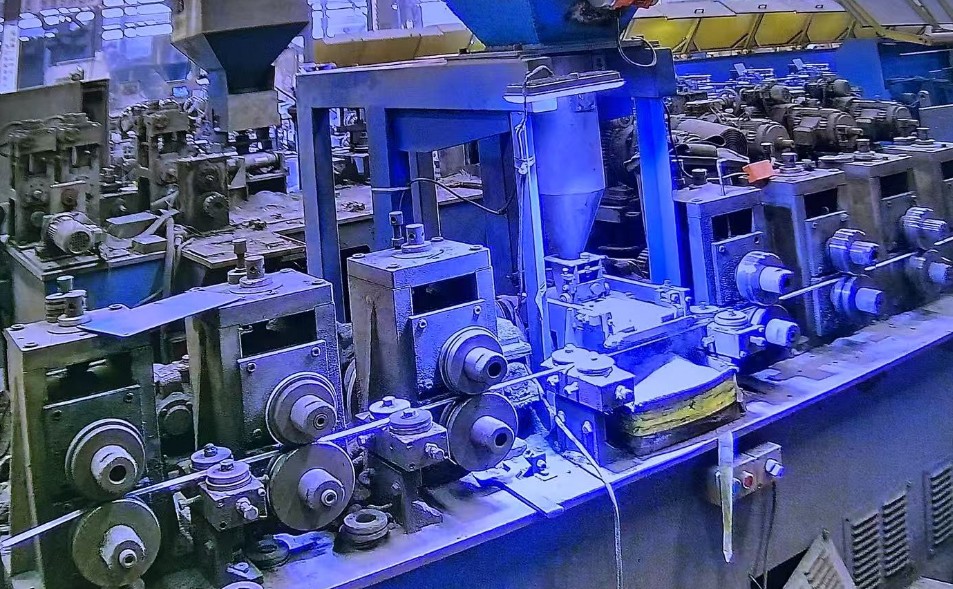

3. Comprehensive process matching Taking into account the customer's production equipment and processing conditions, Xinyuan Broadcom designs personalized process solutions for wear-resistant plate cladding, including recommending suitable welding equipment, determining appropriate welding current, voltage, welding speed and other parameters, and planning a reasonable welding sequence and number of welding layers.

For large wear-resistant plate cladding, a multi-pass and multi-layer welding process is developed to ensure uniform thickness and stable quality of the cladding layer, while preventing deformation caused by welding thermal stress. For example, in the cladding of wear-resistant plates for large crushers in mines, a specific welding method is used to effectively control deformation.

For some wear-resistant plates with high requirements for surface flatness, such as conveyor wear-resistant plates in automated production lines, fine grinding and polishing processes are used after surfacing to reduce surface roughness, ensure smooth and stable material transportation, and reduce material residue and wear