Introduction of Hardfacing Wire:

In the field of Chromium carbide welding wire, our company has a professional team that can provide customers with professional solutions,

Our company independently develops and designs Hardfacing Wire. Hard surfacing wire can greatly improve the wear resistance of the workpiece. Based on the original materials, Overlay Flux Cored Welding Wire can greatly reduce the replacement rate of equipment, extend the service life of equipment, and reduce production costs for our factory.

Advantages of hard surfacing wire:

Our Chromium carbide welding wire has better welding quality. Different chemical compositions are adjusted according to different factory situations and working conditions. Our Hardfacing Wire has less spatter and small deformation. At the same time, hard surfacing wire can also ensure excellent mechanical properties. and metallurgical properties. Our Overlay Flux Cored Welding Wire uses advanced technology to ensure the welding surface is strong and resistant to wear and friction, meaning your equipment can keep operating efficiently in harsh environments for longer. Our Chromium carbide welding wire is designed with ease of construction in mind, ensuring the welding process is simpler and more efficient.

Why choose us:

We have rich production experience and a professional team that can provide you with customized Hardfacing Wire solutions to meet the needs of different equipment.

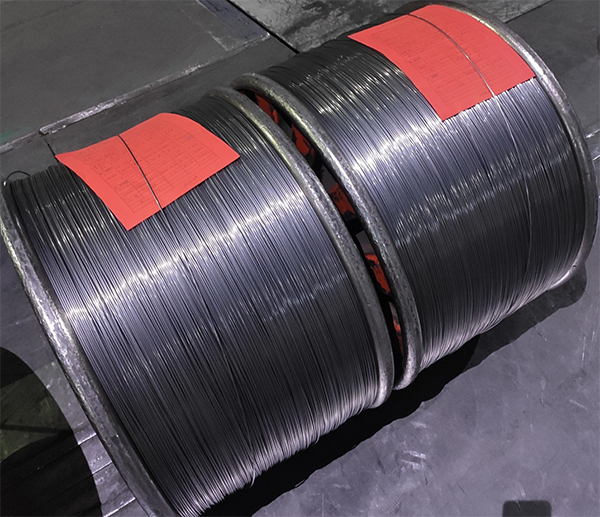

We adopt advanced hard surfacing wire production technology and strict quality control system to ensure that each roll of welding wire meets high standards.

We focus on communication with customers and provide a full range of pre-sales, sales and after-sales services to ensure that you receive the best support throughout the entire cooperation process. We continue to invest in research and development, launch Overlay Flux Cored Welding Wire that meets market demand, and maintain our leading position in the industry.

About us:

Our company's technical team has deeply studied the wear-resistant surfacing welding process, continuously developed and innovated with self-developed welding wires, and gradually launched products such as wear-resistant plates, wear-resistant pipes and derivative wear-resistant structural parts. Off -line surfacing and repairing grinding rollers and grinding discs are also launched at the same time, providing customers with high-quality and reputable services. Adhering to the spirit of craftsmanship and continuously improving the manufacturing process, we not only provide customers with excellent products, but also solve the problem of industrial wear and tear for customers. The products are well received by users and have been unanimously recognized.