Processed Wear-Resistant Composite Steel Plates in Mining Applications

Processed wear-resistant composite steel plates play a critical role in mining by resisting abrasion, extending equipment lifespan, and reducing operational costs. Custom-fabricated for harsh conditions in extraction, conveying, and crushing, they solve rapid wear and frequent replacement issues of conventional steel.

I. Core Applications: Full Mining Cycle Coverage

Deployed across "extraction → conveying → crushing → washing" processes:

1. Extraction: Roadheader pick holders, shearer drum guards

2. Conveying: Conveyor roller sleeves, chute/hopper liners

3. Crushing: Crusher jaws, impact plates, hammer mill liners

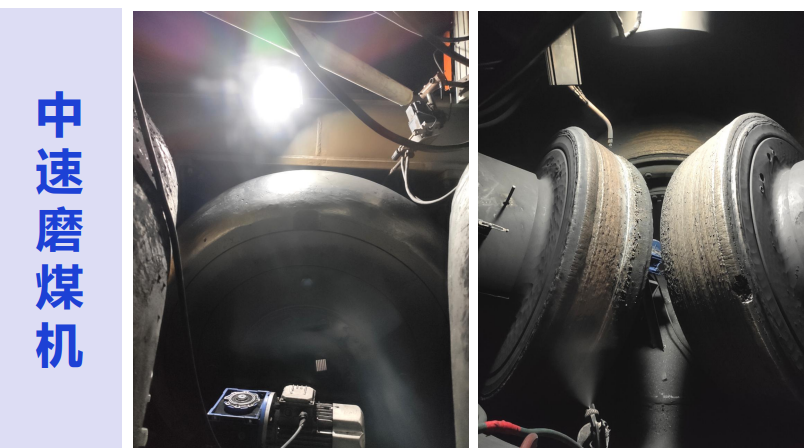

4. Processing: Ball mill liners, classifier blades

II. Key Value Proposition: Solving Mining Pain Points

(Base: Low-carbon steel | Cladding: HRC55-63 alloy layer)

1. Extreme Wear Resistance

•Withstands Mohs 6-8 ore (e.g., granite, iron ore)

•5-10× longer life vs. standard steel (Q235):

•Chute liners: 6-12 months vs. 1 month

•Crusher jaws: Prevents impact fractures + wear

2. Extended Equipment Lifespan

•Ball mill liners: 12-18 months vs. 3-6 months (Mn13 steel)

•Reduces critical "wear part" replacement frequency

3. Lower Operational Costs

•Unit-time cost: 1/3–1/2 of conventional steel

•Downtime reduction: e.g., 10+ fewer annual shutdowns for conveyor chutes

•Saves hundreds of thousands in lost production

4. Complex Scenario Adaptation

•Cutting (plasma/laser): Custom shapes for curved chutes

•Welding (low-hydrogen rods ≤180A): Ensures joint integrity

•Bending (cold/hot): Forms arcs without damaging cladding

III. Processing Compatibility: Preserving Performance

Critical techniques ensure no degradation of wear layer/base metal:

•Thermal Control: Plasma/laser cutting prevents hardness loss

•Crack Prevention: Low-heat welding avoids base metal embrittlement Technical Impact

Processed composite plates enable continuous, efficient, low-cost mining operations – from roadheader guards to crusher components – making them indispensable for modern mine optimization and cost reduction.